In this article we take a closer look at the Graco FinishPro HVLP 9.5 pump.

In addition to the technical data, we will look at the possible applications of this low-pressure paint station, the design and functionality as well as the scope of delivery.

Technical Details Graco FinishPro HVLP 9.5

Here is a short summary of the technical data of the HVLP 9.5 :

- Voltage: 230 V

- Turbine power: 1600 Watt

- Turbine: 5 degrees

- Back pressure: max. 0,7 bar

- Sound level: 96,3 db (A)

- Weight: 11,8 kg (turbine) with hose and spray gun (16,3 kg)

Graco FinishPro HVLP 9.5 – Application Area and Possible Projects

HVLP low pressure spray guns are generally used for low viscosity materials such as lacquers or varnishes. In the field of painting, this sprayer can be used for doors and door frames, windows or radiators, for example. Small surfaces such as woodwork in kitchens or bathrooms can also be sprayed with the HVLP 9.5.

Thanks to the vacuum technology in the bucket system, working at height is also possible without any problems. Railings or fences can also be painted well with the HVLP technology. The system offers advantages, especially when it comes to small and occasional work, such as narrow struts on staircase railings or a wrought iron fence.

Painting a door with the Graco HVLP 9.5

Construction and functions of the Graco HVLP 9.5

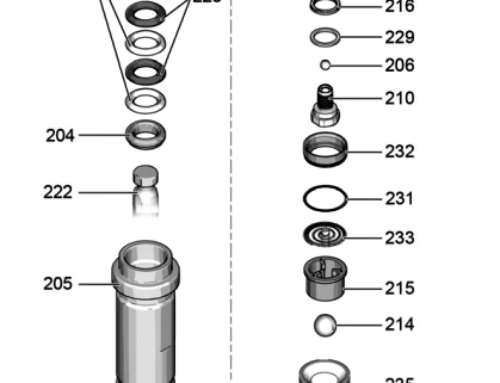

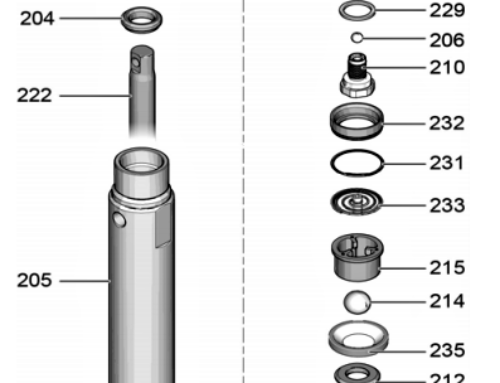

The Graco FinishPro HVLP 9.5 includes the turbine, hose with whip and Edge II Plus gun. The turbine draws air into the cup through the hose in front of the gun. There, the air moves the material and pushes it through the nozzle. The material is atomized at the nozzle and sprayed onto the object being painted.

In simple terms, the turbine works like a vacuum cleaner in reverse and is operated by the red on/off switch. There are three positions on this switch: position 0, position I and position II. In position 0 the paint unit is deactivated, in position II the blower runs continuously. Position I includes Smart Start technology, an automatic control that shuts off the turbine when it does not need air. This reduces wear and tear and noise. The air supply to the 5-stage turbine is controlled by the rotary knob next to it. The Turbocontrol system indicates the set air volume by means of a LED bar display. Further to the right is the fuse. On the left side of the turbine is the industrial grade air filter and a compartment for storing the nozzles and gun needles.

The 9 meter long air hose can be mounted on the front of the turbine in a few simple steps. A 1.2 meter long whip is attached between the air hose and the gun. This whip is much more flexible than the main hose and makes it easier to guide the gun more often.

Adjustment on the Graco Edge II HVLP gun

The Graco Edge II Plus gun offers optimal control, as the material and air volume can be adjusted on the gun. The spray width of the nozzle can also be changed. It is possible to work horizontally and vertically. In addition, the spray pattern can be adjusted from 0.3 to 10 cm, from flat to round spray. The Flexliner cup system allows for overhead work, as the paint is sucked in through the vacuum and not through a suction tube in the cup.

The cup system allows for quick cleaning and also quick paint changes. The nozzle and needle can also be changed in a few simple steps without tools thanks to a quick change system.

Delivery of the Graco HVLP 9.5

- Graco FinishPro HVLP PROCONTRACTOR 9.5

- Graco HVLP EDGE II Plus gun with FlexLiner system, material, air volume and spray width control

- Needle set #3 (1.3mm), #4 (1.8mm), #5 (2.2mm)

- Air hose 9.0 m

- Air hose with whip end 1.2 m

- 3 x 1 liter FlexLiner

- Instructions for use

Graco FinishPro HVLP 9.5 Pump Accessories

Love our content? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Questions or queries?

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form or email us. If you wish to purchase one of the products mentioned above, you can check them out in our online store. You can also visit us at our service base during office hours.

Fill out a Contact Form on our website