What are the best AirCoat paint sprayers for carpenters and cabinetmakers?

We hear this question regularly. Our answer has always been: it depends on what the carpenter wants to do with the paint sprayer. There are indeed many aspects to consider. Starting with the materials to be used, the delivery rate of the machine or the compressor power. For this reason, the following article is an initial guide which can help you get an overview of the available aircoat paint sprayers as well as many performance features.

Wagner SuperFinish SF 23 Plus – AirCoat paint sprayer

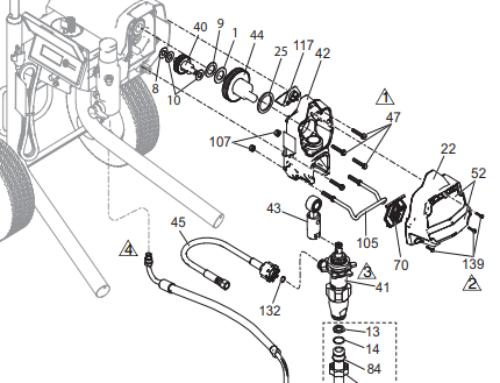

The Wagner SF 23 Plus is quite versatile and displays a variety of features, which can be used to optimally adapt the painting machine to the existing painting operations. For easy transport, a model variant is available on a cart, there is also a version of the Aircoat painting machine on a stand. A version with an integrated compressor is also available, which means no extra compressor has to be transported since the compressor is already installed in the painting machine. Most carpenters use an aircoat spraying machine to process small amounts of material, which is why, as a rule, an upper container with a capacity of 5 liters is sufficient. This upper container functions like a funnel for filling the material. If larger quantities of material are to be processed, the SF 23 Plus can also be equipped with an intake pipe. This allows the lacquer to be sucked in directly from the tank.

The Wagner SF 23 Plus is an electrically operated diaphragm pump with a max. delivery rate of 2.5 l / min. The maximum working pressure is 250 bar and the maximum nozzle size is a 0.023 inch. The SF 23 Plus paint sprayer is powered by an electric motor (230 V). The supply of additional compressed air is achieved by means of an external compressor, but there is also a variant available in which the compressor is integrated. This solution is especially suitable for carpenters, varnishers or exhibition builders who want to use the Wagner SF 23 Plus mobile.

Wagner Cobra 40-10 AirCoat paint sprayer

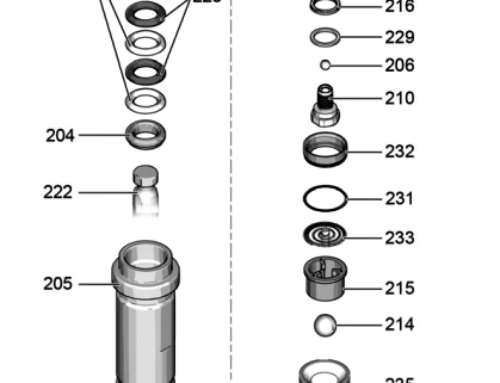

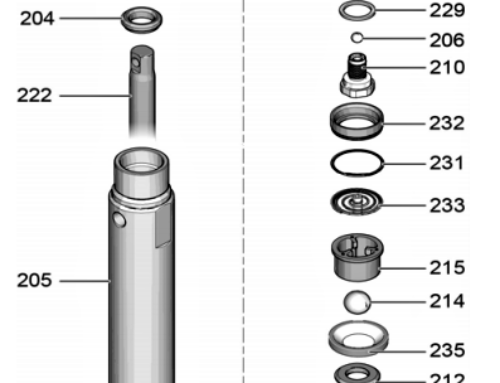

The Wagner Cobra 40-10 is a compressed air-operated diaphragm pump with characteristics that meet the explosion protection requirements. The Wagner Cobra 40-10 has a maximum capacity of 2.0 liters per minute at a maximum pressure of 250 bar. The ratio of the diaphragm pump is 40:1. This means 1 bar of air inlet pressure producing a spray pressure of 40 bar, 2 bar of input pressure 80 bar of spray pressure etc. The aircoat painting sprayer is supplied with a 5 liter upper container, but also a system for the direct suction from the paint container is available. The double membrane of the Cobra also enables high-quality processing of moisture-sensitive and pre-mixed 2-K materials.

Wagner Puma 28-40 AirCoat for carpenters and carpenters

The Wagner Puma 28-40 is a compressed-air piston pump, available in various equipment variants for carpenters and cabinetmakers. The Puma 28-40 is available as a mobile version on a trolley, as a stand with four legs or as a stationary aircoat sprayer with wall mount. In addition, there is also the possibility of spraying lacquer directly from the material container via a top container of 5 liters or via a suction hose. The Puma has a maximum delivery rate of 2.4 l / min with a maximum working pressure of 244 bar. The piston pump operates with a ratio of 28: 1 at a maximum air inlet pressure of 8 bar. The largest nozzle is a 0.023 inch bore. This painting machine can also be used by carpenters who spray paints containing solvent and meets the requirements for work in explosive areas.

How to find the best Aircoat painting machine for carpenters and cabinetmakers?

Here is an overview of the essential points that should be clarified when selecting an aircoat paint sprayer in order not to buy the wrong painting machine for your carpentry projects.

- what materials and quantities should be processed with the aircoat painting machine?

- which nozzles and filters are required for the material to be sprayed?

- should the painting machine be equipped with a funnel for small quantities or a suction hose to pump the lacquer directly from the container?

- engine type: electric or air-operated aircoat?

- mobility: should the painting machine be used stationary and at one location or should it be mobile?

- compressor: what is the power of the compressor?

- explosion protection: will highly flammable paints and spraying materials be processed?

- aircoat or airless?

- cost-effectiveness: is the purchase of an aircoat painting machine worth the money for my projects?

For detailed advice on your carpeting projects, please do not hesitate to contact us at our service center, by telephone at the 0049 (0)30 – 22015436 or by email via our contact form.