Reduce overspray by improving your spraying technique, setting the right pressure, choosing the right spray tip or using a helpful accessory. This article covers each of these suggestions in depth and includes a video presentation on the topic (Reduce overspray Part I and Part II)

What is Overspray?

“Overspray” is technically defined as fine paint particles collecting on nearby surfaces, due to the atomization of the material created by paint spraying.

The term overspray amongst amateur- and professional painters has sometimes been loosely defined as “any time you are getting paint onto an area you didn’t intend to put there in the first place”. However, not all over-spraying is the same thing, and the causes are usually quite different, requiring alternative solutions.

To reduce overspray, we will look at the correct spraying technique, selecting the right equipment and your choice of optional accessories that will make airless paint spraying easier and can reduce overspray in the process.

Spraying Technique

Airless sprayer manufacturers have constructed the spray tip, tip holder and gun to operate at an optimal distance and angle from the work surface. You will be off to a good start if you can remember and practice the following:

Keep the gun 25cm from the surface; and

Point the spray tip and holder perpendicular to the wall.

When pulling the trigger, move the gun at the same time. Move your hand at the same pace you would use when closing a curtain. Use your feet and move your body to maintain the spraying distance and angle of the spray gun to the surface. The use of extensions and swivel joints will assist you in reaching wider surface areas and getting around obstacles.

Typical action resulting in overspray

Aiming the gun away from the surface.

Spraying too far away from the working area (i.e a distance greater than 25cm).

Spray Pressure

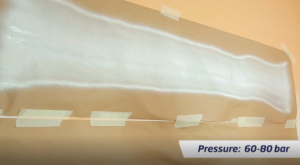

Optimal spraying pressure is essential to reduce overspray, so that there is not an excess of paint particles being released into the air. Of course, airless paint spraying requires the atomization action to produce the spray fan and an even area coverage, however, when spraying at very high pressures, a fine particle mist will quickly develop and fall on surrounding surfaces.

Finding the right spray pressure for your job requirement is a combination of knowing what factors influence spray pressure and what to look out for when spraying. When the pressure is too low, your spray pattern is uneven, with “fingers” forming within the spray pattern and thin segmented bands forming at the top and bottom (when spraying in a horizontal motion). When the pressure is too high, material is being forced out of the tip hole at a much greater force than required to get the job done.

With everything else being equal, your working pressure will change based on these factors:

- Higher viscosity material (e.g. plaster, weather-resistant exterior emulsion paints) requires higher pressures, lower viscosity materials (e.g. lacquer) require lower pressures.

- Delivery rate of the machine.

- Spray tip selection.

- Temperature of the material. Heating a material raises its viscosity, meaning it requires less pressure for the same spray fan pattern result.

- A longer hose will decrease the working pressure. If you are working on scaffolding with the Airless sprayer on the ground, the material must also fight gravity when traveling up the hose, which will also reduce the pressure acting in the gun (point of material delivery onto the surface).

- Diameter of the inlet pipe. Smaller sizes will reduce the working pressure.

If the machine doesn’t seem to be performing efficiently. Check for obstructions, clean the filters and replace worn out spray tips.

Too little

Your spray pattern looks segmented with a thin band at the top and bottom. Streaking or “fingers” are present within the spray pattern. The coat looks too thin, and your immediate instinct is wanting to paint over it again. (This is different from jobs simply requiring two coats of paint.)

Too much

The paint begins to run, with drips running over and down the spray pattern. A visible mist surrounds the working area.

Just right

At an optimal pressure setting, the spray fan pattern has uniform coverage with no visible fingers or segments at the top or bottom.

Finding the right spray pressure: step by step

To find the optimal spraying pressure:

- Begin on a low setting and make a test spray.

- Check the spray pattern for fingers and decide if you happy with the coverage.

- Increase the pressure incrementally, until there is an even surface coverage, with no fingers present or visible segmented paint areas.

With experience using the same machine, you will have a good understanding of what materials will require particular pressures, without needing to do rigorous testing each time.

Typical action resulting in overspray

Airless equipment pressure setting too high. Find the optimal spray pressure using the steps outlined above.

Spray Tip

There is quite some contention amongst professionals painters regarding which spray tips produce the most- and least overspray. There isn’t a “one-size-fits-all” approach as your spray tip will depend on your gun setup, spraying process and material being used. You may also be limited to your choice of spray tip if the it is a niche job e.g. road markings or heavy-duty materials.

At the very least, make sure you match the spray tip with the material you are using and the job requirement. Paint and other materials will include a “recommended spray tip sizes” in their technical data sheet. Make sure your gun filters are clean and you are operating the machine at the optimal pressure. To reduce the pressure, select a tip with a smaller bore hole. To reduce the spray fan, choose a spray tip with a lower starting digit.

When investigating and researching spray tips that produce the least overspray, the two most cited options are flat tips and low pressure tips.

Flat tips

Some older professional painters opt for the flat tips that are used with fine cone filters at the tip of the spray gun (barrel of a normal gun). It is claimed that the edges of the flat tips are smoother and have less interference than reversible tips, and thus produces less overspray. Since this tip design is outdated, we are not convinced that this tip produces less overspray than the newer designs, and may have more to do with the technical expertise of expert painter sprayers.

Product examples:

- Titan Flat Tips

- Graco Flat Tips

Low pressure tips

Spray tip manufactures have improved the technology of spray tip designs so that they can operate at lower working pressures. At lower pressures, less material is finely separated into the air, which will reduce overspray. Low pressure tips are longer lasting and easy to use – with colour coding and number codes to ensure you know which tip you are using.

Product examples:

- Graco FF LP Tips and LP Tips

- Wagner HEA ProTip

- Titan TR1 HEA Tip

Typical action resulting in overspray

Tip size selection incorrect for the job requirement or material.

For more information on selecting the right spray tip, have a look at our ultimate guide for choosing the right spray tip (article)

Masking, Plastic Covering and Shields

For completeness we must mention that in most cases, overspray can never be completely eliminated. So it is best to cover important furniture items with a plastic covering and mask and cover fixtures and fittings as appropriate. When working outside, you can use the same plastic covers to pull back and cover small trees and shrubs.

A cardboard “shield” attached to an extender, is used as a cheap and reliable trick to control some of the overspray, especially when working outside. The cardboard can also be used as a surface to start and stop the spraying fan action, so that an even pattern is produced on the working surface. This is especially true when using an extension without a second valve.

Typical action resulting in overspray

Covering every surface with plastic, cardboard and other protective coverings is a costly and time-consuming process. It’s always best to ensure you have the correct spraying technique and using your equipment properly, with the optimal spray pressure setting before resorting to covering all surrounding objects and blocking the overspray at every opportunity. Of course, do your standard masking and covering as usual when working inside and out, but if you worried about overspray landing on cars parked on the other side of the street, you likely spraying incorrectly to begin with!

Extensions or Lances

FARBMAX spray extension

When working on wider surface areas, especially on exterior walls, having some extra reach will ensure you keep the gun distance and spray angle within an optimal working position.

An extension that sits between the tip holder and the gun itself is available in various sizes starting at 25cm, and going all the way up to 180cm!

Extension threads come standard in 7/8 inches to fit most modern guns. If you have older gun models you may need an adapter to convert the 11/16″ to a 7/8″.

Product example: FARBMAX extensions

Some professional painters feel that using extensions always increases overspray, while others feel the use of extensions makes work flow much easier, allowing them to maintain an optimal working distance from the spraying surface. Its probably best to try it out for yourself and see which works best for you.

An unfortunate new issue emerges when using extensions and that is the formation of droplets on either side of the spray pattern. When pulling or releasing the trigger, the pressure lag created in the extension results in thicker paint droplets being released from the spray gun, called “spitting”. Manufacturers have developed a second valve to go at the end of the extension, that also have a swivel feature. This means you can adjust the angle of the spray fan without getting the residual spitting that usually occurs when using simple extensions.

Graco Overspray Control Set OFS

Product example: Graco “Clean Shot” Valve

(Shown in picture left, with red tip holder and yellow spray tip.)

Airless equipment companies have combined these two concepts above to produce a reduce overspray kit. In the product example, Graco includes a Contractor gun and a LineLazer spray tip.

Product example: Graco Overspray Control Kit (OFS)

The set comes complete with Contractor gun and spray tips (321 and 419)

To combat spitting, you have two options:

- Begin spraying just off the area you want to work on and finish just off the painted area.

- Use a second valve attached to the front of the extension.

Typical action resulting in overspray

Overspray is reduced, but spitting may occur. Its recommended to use a second valve with your extension, an overspray kit or use a roller attachment.

Rollers

When priming drywall, painters have opted to spray and back-roll to ensure the material binds properly to the surface. This usually means two painters work in tandem, one does the spraying and one does the rolling. Back-rolling was also used as a precautionary measure to produce a paint texture that can be painted over with a smaller roller if touch ups needed to be done after the initial coats of paint were applied. By using a roller, you ensuring the same texture for all coats is maintained.

Storch LeOS

To alleviate the need for a second painter and to reduce spitting from the extension, companies like Graco and Storch have introduced a sprayer / roller combo accessory kit. A roller is attached to the extension arm and remains fixed, while the spraying mechanism is adjustable. The standard gun is replaced with an “Inline” gun, which makes it easier to fire the trigger and handle when rolling. With the spray tip and holder aimed below the roller, spray and roll on the down stroke and only roll on the up stroke. Some paint and overspray is caught in the roller, reducing overspray being released to surrounding areas.

Product example: Storch LeOS

“LeOS” stands for “LEss OverSpray” and is a kit that comes with an extension, a second valve with the ability to swivel and a roller attachment.

Wagner Inline Roller IR100

Another option to eliminate overspray completely is to substitute the spray tip and holder for a complete roller extension, so that the material passes into the roller itself. There is thus no atomization and no resulting overspray. The benefit of having the combo action of the roller application with the airless sprayer paint delivery, is that you need not worry about overspray and working time is reduced as you do not need to return the roller into the paint bucket each time – paint is delivered straight into the roller, via the inline gun and extension and applied onto the surface with a rolling action.

Product example:

Typical action resulting in overspray

None. Overspray is controlled and atomization minimised using a roller attachment, or eliminated completely with the complete roller head with direct paint delivery.

Heated Hose Systems

Another alternative is to simply heat the material you are working with. When the material is heated to a temperature of between 20 and 60 degrees, it increases its viscosity and thus moves easier within the pump and hose, requiring less pressure to achieve the same desired spray pattern. Heated hose systems are available on their own and compatible with most machines, or bought together with the Airless sprayer.

Product Example:

Wagner SF23 TempSpray (on cart with wheels – picture left)

Wagner SF23 TempSpray (on stand – carry version)

This may be an ideal solution for working in colder environments and/or with longer hose lengths.

Conclusion

Overspray on furniture, fixtures, plants and vehicles can be a nightmare for painters. Reduce overspray concerns by taking care to follow the guidelines, take precautionary measures and learn how to master your equipment. The technology improvements and accessories are designed to make your job easier, but make sure you have learnt proper Airless spraying technique first!

For any further questions regarding overspraying, you can contact us on +49 (0) 30 220 15436, fill out our contact form below or email us. If you wish to purchase one of the products mentioned above, you can check them out in our online store. You can also visit us at our service base during office hours.

Love our content? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Questions or queries?

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form or email us. If you wish to purchase one of the products mentioned above, you can check them out in our online store. You can also visit us at our service base during office hours.

References

- What is overspray. https://www.detailingwiki.org/detailing-miscellaneous/what-is-overspray/

- Graco. Low Overspray CleanShot Valve.

- Graco. Low Overspray Kit PDF.

- Storch. Airless-LeOS SprayRoller (German version)

- Wagner. TempSpray Airless heated hose systems PDF.