Airless Q&A #14 – In the new video of our series “Airless Q&A” we discuss hose whips on paint sprayers. A hose whip is mounted between the hose and the gun, giving more freedom of movement and flexibility. The hand is relieved of the full wight of the main hose, the optimal distance and angle between the gun / nozzle and the surface can be maintained more easily and so less overspray is created when working.

What is the advantage of using hose whips on Airless paint sprayers?

Using a whip makes it easier to guide the gun, as less pressure is transferred from the hose to the user’s hand, making it easier to handle the spray gun while spraying. This also makes it easier to guide the gun at the optimum distance from the surface (25-30 cm) and at the correct angle of 90 degrees. By maintaining the optimum distance and the correct angle of spray of the paint, the formation of overspray is reduced or prevented. Here are the advantages of hose whips at a glance:

- relief for the hand / wrist

- optimum distance to the surface is easier to maintain

- optimum angle to the surface can be more easily maintained

- this can reduce the development of overspray

For thicker materials such as plaster or putty, the lower weight of the hose whip is a great benefit for dealing with the heavier weight of the main hose.

Which whips are there? Which one is the right one?

There are hose whips in different lengths and different inside diameters. Various threads are also available, so there are hose whips suitable for almost all applications. Thinner whips with a smaller diameter and a rather small thread for paint applications, slightly thicker for dispersion and longer whips with a larger diameter and thread for, for example, spraying plasters or putties.

Here is an overview:

Wagner hose whip

Here is an overview of the available hose whips of the manufacturer Wagner:

• Wagner hose whip (metal mesh), DN5 (inner diameter 5 mm), max. Pressure 250 bar, thread: 1/4, length 1 m – 9984458 – order here (alternative hose whip)

• Wagner hose whip (metal mesh), DN5 (inner diameter 5 mm), max. Pressure 270 bar, thread: M16x1,5, length 1 m – 9076314 – order here

• Wagner hose whip, DN6 (inner diameter 6 mm), max. Pressure 270 bar, thread: M16x1,5, length 2,5 m – 9984569 – order here

• Wagner hose whip, DN10 (inner diameter 10 mm), max. Pressure 250 bar, thread: 3/8, length 2.5 m – 2336582 – order here (alternative hose whip)

Graco hose whip

Here is an overview of the available hose whips of the manufacturer Graco:

• Graco Bluemax II, inner diameter 3/16, max. Pressure 227 bar, thread 1/4, length 0,9 m – 238358 – click here (alternative hose whip)

• Graco Bluemax II, inner diameter 3/16, max. Pressure 227 bar, thread 1/4, length 1.4 m

• Graco Bluemax II, inner diameter 3/16, max. Pressure 227 bar, thread 1/4, length 1,8 m – 238359 – order here

• Graco Bluemax II, inner diameter 1/4, max. Pressure 276 bar, thread 1/4 (F) x 3/8 (M), length 0,9 m – 277249 – click here

• Graco Bluemax II, inner diameter 1/4, max. Pressure 227 bar, thread 1/4 (F) x 3/8 (M), length 0,9 m – 241735 – click here

• Graco Bluemax II, inner diameter 3/8, max. Pressure 227 bar, thread 1/4 (F) x 3/8 (M), length 0,9 m – 277351 – click here

• Graco Bluemax II, inner diameter 3/8, max. Pressure 227 bar, thread 3/8, length 3,5 m – 191239 – click here (alternative hose whip)

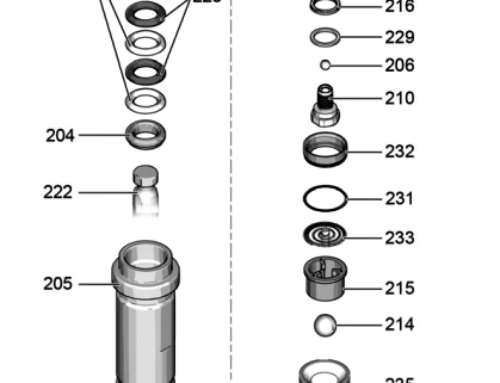

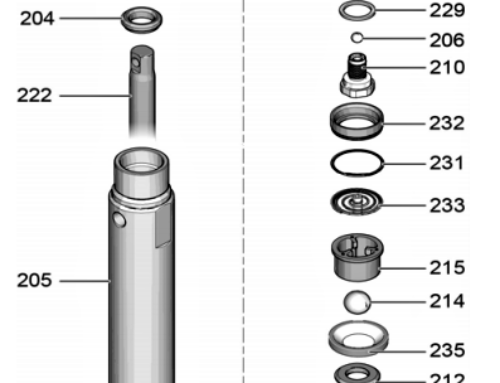

How are hose whips attached?

Hose whips are mounted between the main hose and the gun. In doing so, the thread of the main hose, hose whip and gun should be taken into account so that everything fits together. For connecting the main hose and the whip an adapter is usually needed. Depending on the thread of the hose and hose whip you should select a suitable connector for connecting.

Here are some examples of connectors between main hose and hose whip;

Love our content? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Questions or queries?

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form below or email us. If you wish to purchase one of the products mentioned above, you can check them out in our online store. You can also visit us at our service base during office hours.