Heated hose systems, such as the Wagner TempSpray, offer useful benefits for those working with Airless paint sprayers. Using a heating hose system allows the painter or carpenter to heat the spray material to a desired temperature, influencing the spray properties of the paint, resulting in better workflow and improved surface coverage.

The higher temperature lowers the viscosity, making the spray material more fluid. Heated paint and other heated spray material can be sprayed at lower pressures, greatly reducing the amount of mist in the air and overspray.

Less paint overspray means a cleaner working environment with the Airless paint sprayer, increased life span of the device and operational parts; and reduced cleaning time.

Watch our introductory video on heating hose systems…

What is a heating hose system and how does a heated hose work on an Airless paint sprayer?

A heated hose is used with an airless sprayer unit to improve the application of the material onto the working surface by heating the spray material (eg emulsion paints). The heated hose replaces your standard hose and is connected to the Airless paint sprayer in the same way. The airless unit draws in the paint and generates the pressure, the paint is then pumped through the heated hose before entering the spray gun. You operate the spray gun as usual.

The hose contains a heating filament that heats the paint to temperatures ranging from 20 degrees to 60 degrees as it flows through the hose. At the front end of the heating hose a normal airless spray gun can be attached. However, since we are dealing with higher temperatures, its recommended to use a heat-resistant glove or choose a spray gun with a handle that is isolated from the paint inlet pipe to protect the user’s hand from overheating.

An isolated spray gun handle means the heated material passes through a separate inlet pipe and into the spray gun mechanism, keeping the palm of your hand protected from extreme heat.

There are also handles which have an extra plastic grip that also provides a protective function. Air-assisted paint sprayers and guns, such as the AC4600, have both the separate inlet pipe for the heated material and the inlet pipe for the air, with an ergonomically designed grip for extra comfort and improved control.

In addition to the heated hose, a control unit is mounted either on the sprayer or the hose trolley, which allows the desired temperature of the paint can be adjusted. The temparature readout is displayed in red digits on the front of the device.

Advantages:

- Less paint mist & less overspray.

- Preparation time reduced, as less masking and covering of surfaces is required.

- Widens the application areas of the spraying device. including sensitive areas that were susceptible to overspray.

- Saving and waiving dilution (VOC directive)

- Higher layer thickness possible when applying paint

- Less wear on the sprayer and operational parts, due to lower working pressures.

- Workflow also improved with lower spraying pressure.

- Lower performance requirements of the Airless sprayer (use of smaller and more cost-effective sprayers are now possible).

- Materials remain at the ideal working temperature regardless of how cold the external environment is. This is especially useful for early morning or evening spraying when the temperature drops, or for climates that experience much colder temperatures.

- Liquids that needed to be diluted may instead be heated, to create the same desired effect.

Disadvantages:

- Additional costs, mainly being the purchase price of the heated hose.

- Maintenance costs of the heated hose, however the heated hose system may reduce overall maintenance costs of operating the machine.

- A heavier, clunkier hose.

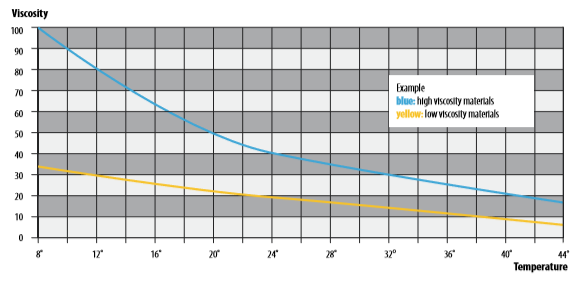

Viscosity Table

The following table illustrates the effects of temperature on the viscosity of high- and low viscositymaterials and thus the processing properties.

Viscosity Table

Heating Hose Products

The Wagner Nespray and Nespray Plus models as well as the Wagner TempSpray models are all heating hose systems available.

We will look at the following products featured in the Wagner TempSpray Heated Hose Systems, to give you a better idea of what to expect from a heated hose system. These are the H 126, H 226, H 326 and H 426.

Wagner TempSpray H 126

Designed specifically for paint materials and general purpose paint jobs. This heating hose system is compatible and can be adapted for most Airless devices.

Applications:

- Wood impregnation

- Oils

- Stains

- Glazes

- Primers

- Undercoats

- Fillers

- Lacquers

- 2K materials (watch the pot life)

Suitable for all Wagner SuperFinish devices (SF23, SF27, SF31) and the Wagner Cobra models.

Technical specifications:

Wagner TempSpray H126 – Lacquer work in window frame

- Voltage: 230 V – 50 Hz

- Heating power: 600 W

- Hose: DN6 / 10 m stainless steel

- Max. Working pressure: 250 bar

- Temperature control: 20 – 60 ° C (continuous)

- Weight: 3.5 kg

Delivery:

- Base unit H 126, 1/4″

- Stainless steel hose DN6, 10m

- Wagner AG 08 TS gun

- TradeTip 3 nozzle holder (with gun), F-thread

- 2SpeedTip spray tip L10 208 / 510

Wagner TempSpray H 226

Designed for emulsion and latex paints, this heated hose is mounted on a trolley and cart for easy transportation to and from the work site.

Applications:

- Thick film materials

- High solids

- Emulsion paints

- Latex paints

- Facade protections

- Roof coatings

Suitable for all Wagner SuperFinish devices (SF23, SF27, SF31), all Wagner ProSpray (eg PS PS 3.25 and 3.39) and HeavyCoat models (HC950 & HC970).

Technical specifications:

Wagner TempSpray – spraying wooden facade

- Voltage: 230 V – 50 Hz

- Heating power: 1300 W

- Hose: DN10 / 15 m PU sheath

- Max. Working pressure: 250 bar

- Temperature control: 20 – 60 ° C (stepless)

- Weight: 18 kg

Delivery:

- Base unit H 226, 1/4″

- Hose reel

- Heated hose yellow DN10, 15m

- Hose whip 1/4″ DN4, 1m

- Wagner AG 14 gun

- TradeTip 3 nozzle holder (with gun), F-thread

- 2SpeedTip spray tip D10 111 / 419

Wagner TempSpray H 326

Designed for emulsion and facade paints, this sprayer has almost identical technical specifications as the H 226, but comes with double the hose length.

Applications:

- Thick film materials

- High solids

- Emulsion paints

- Latex paints

- Facade protections

- Roof coatings

- Corrosion protection

- Bituminous media

- Adhesives

Suitable for Wagner SuperFinish 31 and SF 7000, Wagner ProSpray 3.39 and all HeavyCoat models (HC950 & HC970).

Technical specifications:

- Voltage: 230 V – 50 Hz

- Heating power: 1100 W

- Hose: DN10 / 30 m PU sheath

- Max. Working pressure: 250 bar

- Temperature control: 20 – 60 ° C (stepless)

- Weight: 23 kg

Delivery:

- Base unit H 326, 1/4″

- Hose reel

- Heated hose yellow DN10, 30m

- Hose whip 1/4″ DN4, 1m

- Wagner AG 14 gun, F-thread

- TradeTip 3 nozzle holder (with gun)

- 2SpeedTip spray tip D10 111 / 419

Wagner TempSpray H 426

Spraying plaster or other high-viscosity materials and looking to improve spraying performance? This heating hose system features a wider hose cross-section and combines superbly with the Wagner HeavyCoat models.

Wagner TempSpray H 426

Applications:

- Heavy corrosion protection

- Plaster

Suitable for Wagner ProSpray 3.39 and all HeavyCoat models (HC950 & HC970).

Technical specifications:

- Voltage: 230 V – 50 Hz

- Heating power: 1300 W

- Hose: DN19 / 15 m PU sheath

- Max. Working pressure: 250 bar

- Temperature control: 20 – 60 ° C (stepless)

- Weight: 19 kg

Wagner TempSpray – spraying corrosion protection

Delivery:

- Base unit H 426, 1/4″

- Heated hose yellow DN19, 3/4″, 15m

- Hose whip 3/8″ DN10, 2,5m

- Wagner AG 14 gun

- TradeTip 3 nozzle holder (with gun), F-thread

- TradeTip 3 spray tip 433

Wagner HeavyCoat models work wonderfully with the H 426!

It is recommended to Buy a Heating Hose System When

- If a reasonable portion of your paint spraying working hours are done in colder conditions.

- You want to lower the viscosity of the material you are working with, but are hesistant to dilute it, or when diluting the material is not available.

- You want another alternative for reducing overspray.

- You looking for a softer surface spray finish.

Love our content? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Afterword

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form or email us. If you wish to purchase one of the products mentioned above, you can check them out in our online store. You can also visit us at our service base during office hours.

Fill out a Contact Form on our website

Questions or queries? Fill out a Contact Form here.