Our Airless spray tip guide comprises the video below and our article.

We also have tables to assist you with choosing the right tip depending on the application or identifying the spray tip itself.

1. How to choose an Airless spray tip

Check the Technical Data Sheet, TDS of the material you are using

Your first go-to is the technical data included on the material product label.

Most materials sold today are required to display relevant product information and technical data for suitable applications.

A section for recommended spray tip sizes will be included in the product technical data sheet. (Further down in the article we have recommendations and examples for when you may use a spray tip outside the recommended range.)

Check the product packaging

Some Airless spray tips have clearly stated applications. Some spray tips are highly specialized for certain materials or job requirements.

Manufacturers like FARBMAX, Graco, Wagner and Titan, colour-code their spray tips for easy reference.

They also often state the applications suitable for that specific spray tip on the packaging itself.

| Wagner TradeTip 3 FineFinish (purple) for fine finish applications  |

Graco RAC X (brown) for plaster and thicker materials  |

Titan TR1 Line Striping (white) for road marking  |

Airless Discounter spray tip table

Click the link below or go onto our website and search for “spray tip table” at the bottom of the webpage in the footer menu.

The spray tip table cites the spray tip number followed by suggested applications, the bore hole size, spray angle and filter recommendation.

Click here to view the spray tip table

Common sense using the spray tip number and the job requirements

For the 4th option we need to understand what the spray tip number means. (In-depth explanation in point 2.)

For three digit spray tip numbers, the first number tells you the spray angle (a neat trick using the 2x or 5x rule will help you determine the fan width). Lower numbers 1xx, 2xx, 3xx etc are narrow spray fan widths used for spraying narrow surface areas e.g. staircase railings, trim, cabinets, doors, fences.

Spray tip numbers starting with 5xx or 6xx are used for interior and exterior walls. For four digit spray tip numbers, the first two digits are the spray angle. In this case a 4 digit number starting with 12xx is a very wide spray fan width used for most likely new construction walls.

The second two digits are the bore hole size of the spray tip in thousands of an inch. All manufacturers used the numbering system in inches, but the size can be converted to millimetres when required. Materials with larger particles or higher viscuous materials will require larger bore hole sizes.

Please note: We are making the assumption you are using professional Airless paint spraying equipment. Entry-level sprayers and DIY models often don’t have the sufficient delivery rate or spraying pressure to handle more demanding jobs. If you are unsure whether your Airless sprayer can handle your job requirements please contact us and we can assist you.

2. Understanding the Airless spray tip number

Lets use the spray tip number 515 as an example. The 3-digit number (5-1-5) tells you the spray angle and thus the fan width and the hole size in thousands of an inch. It can be deciphered as follows:

The number 5 in front (5xx)

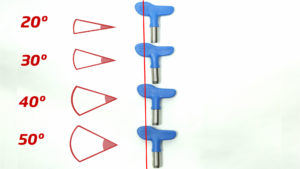

The first number 5 indicates the opening angle with which the airless spray gun ejects the material onto the surface.

To calculate this angle simply put a zero in front of the digit, so for 5 we have 50 degrees, 4 stands for 40 degrees, 3 for 30 degrees, and so on and so on.

To be precise the angle is the spread at which material is expelled through the hole with this angle of atomization.

Spray Tip Number and Spray Angle

2x Rule for determing the fan width using the Imperial system

Take the number in front and multiply by 2, this will give you the spray fan width in inches when held perpendicular, 12 inches from the spraying surface. For our example above, we take 5 x 2 equal to a 10 inch spray fan width.

5x Rule for determining the spray fan width using the Metric system

Take that same number in front and multiplying by 5, will give you the fan width when the spray gun is held perpendicularly, 25cm from the surface. This means that for our above example, a 515 airless spray tip will produce a spray pattern fan width of 25cm (5 x 5 = 25).

If you want to paint a big area, for example a new construction wall, then a spray angle as wide as possible is preferable, with which can cover a large surface. In this case we use a spray tip number of 12xx (4 digit number). This produces a spray angle of 120 degrees and a fan width of 60cm+

For spraying in more detail, for example beams or window frames, a spray tip which allows for more accurate atomization is preferable. In this case, we would choose an Airless spray tip with angle of 20 degrees. For example, the Airless spray tip numbered 211.

A combination of three numbers appears on the head of the airless spray tip. We have already deciphered the first digit of this 3 digit number. That is, the first 5 for the nozzle 515. Now for the second two…

The following two numbers (x15)

The 1 and 5 make up the number 15. This indicates the diameter of the hole through which the material is sprayed. In this case, 15 stands for 0.015 inches. To convert inches to centimetres, multiply by 2.5 times the particular number. For example a 0.019″ hole is equivalent to a 0.048 cm hole, roughly half a millimetre.

Airless sprayers will often cite a maximum spray tip size, expressed as e.g. Max. tip size 0.051” (or 1.2954 mm).

This means the manufacturer suggests to use a spray tip number whose ending does not exceed x51.

Meaning of the spray tip number summary

The first digit tells you the spray angle and fan width.

The second number tells you the orifice size / bore hole size in thousands of an inch.

For spray tips with 4 digits, the first two digits are the spray angle and fan width and last two digits are the bore hole size.

Please note: Spray tip orifice size and volume

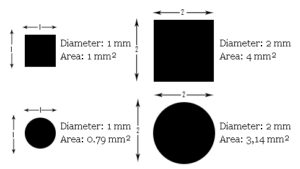

Doubling the size of the diameter of the spray tip, will yield a more than double increase to the volume of material passing through the spray tip. This is because the ratio is non-linear – doubling the diameter is a an almost 4-fold increase to the size of the actual bore hole. (Approximately 3.974 times for radial shaped holes.)

Diameter versus area of squares and circles

3. Spray tip construction

Wagner Spray Tip

The purpose of the spray tip is to produce the desired fan width of the spray pattern and the flow rate. The pump of the machine produces the pressure, which acts against the size of the hole of the Airless spray tip.

Each spray tip will have the follow general specifications:

- A plastic handle – shaped and colour coded. The arrow denotes the direction of the spray and most companies have colour coded tips as a compatibility guide for certain applications.

- A stainless steel cylindrical barrel.

- A tungsten carbide tip.

- A 3-digit or 4-digit number on the handle, which represents the spray angle, fan width and the bore hole size. e.g. 615 for a spray angle of 60 degrees, a fan width of 30 cm (12 inches) and a bore hole size of 0,015 inches.

- Some Airless spray tips will have additional abbreviated letters to further describe their main features. e.g. LP for low pressure, FF for fine finish.

4. Spray tip seat and gasket

Often when purchasing a new spray tip, the product will include a spray tip seat and gasket.

Your spray tip seat and gasket are placed inside the spray tip guard.

The newer spray tip, seat and gasket versions allow you to insert into the spray guard using the bottom of the spray tip.

Change Graco RAC X Tip

Common Graco gaskets

- Black (your standard seal)

- Yellow (solvent or harsh chemicals). E.g lacquer

Common Wagner gaskets

- White gasket used for all materials

Missing the spray tip seat? The spray tip will be slightly looser than usual.

If there is paint leaking out the tip its possible that the spray tip seat is missing or the gaskets are worn.

Customer question: When do you replace the gasket or seal? Since you often receive new gaskets and seals with your new spray tip, we recommend you replace the gasket, each time you use a new spray tip.

Gaskets found in the Airless Discounter store

- White, metal and black standard use gaskets

- Wagner gaskets for TradeTip spray tips

- Graco gaskets for XHD, RAC X FF LP (black) (water-based) and RAC X FF LP (yellow) (solvent-based), RAC X OneSeal and RAC 5 OneSeal.

5. Airless spray guards

Identified by the protruding rails extending from the spray gun nozzle. The spray guard is the housing that holds the spray tip, gasket and seal.

Will the spray guards fit every spray gun?

Threads on the spray guard are universal – the standard size is 7/8” – and fit most spray guns.

You can use Graco guards on Wagner spray guns, and Wagner guards on Graco spray guns. FARBMAX and Titan also use the standard 7/8″ thread, so you should be able to use the spray guards across all models and brands.

Wagner spray guards also have a F-Thread 11/16″ along with the standard G-Thread 7/8″.

The spray guards themselves are both black so be sure to check the size – 11/16″ are smaller and shorter than the 7/8″.

Customer question: Will my Titan spray guard fit my Graco Contractor gun? Yes.

Will the spray tips fit in every guard?

No. Variations in the spray tips themselves in barrel diameter and length means the spray tip won’t always fit snuggly into the spray guard. Take note of the following spray guards and the compatibility with different spray tips.

Graco have the newer RAC X (blue), older RAC V (orange) and XHD RAC (grey) guards.

Wagner have two spray guards, one in black for TradeTip 3 spray tips and one in yellow for low overspray, TwinTip spray tips. In Europe, Wagner also have the black guard in two sizes F Thread 11/16″ and G Thread 7/8″. The F Thread 11/16″ is smaller and shorter than the G Thread 7/8″.

Titan have their No Build Guard (black), Flat Tip Guard (red) and Adjustable Guard (black). These all have a thread of 7/8″ and are interchangeable with most industry spray guns. They have a maximum pressure usage of 345 bar. Titan also have their High Pressure Tip Guard (grey) also with a 7/8″ thread and a maximum working pressure of 530 bar.

FARBMAX also follow the Graco spray guard colour coding for older and new models. With the blue spray guard being their newer version and orange being their older version. The quality remains of a high standard, the only difference is the choice of tips you are using.

Spray Guard |

Spray Tip Compatibility Same Brand |

Spray Tip Compatibility Other Brands |

| LineLazer (yellow) for road marking, older Graco tips (black) (discontinued, choose latest version) | Wagner Trade Tip 3 (yellow, purple, green), Wagner HEA ProTip (green), Titan SC-6+ (red, purple), Titan TR1 Line Striping (white) for road marking and FARBMAX Silver (blue) | |

| RAC X (blue), RAC X (brown), RAC X LP (green) and RAC X FF LP (green) | None | |

Graco XHD RAC SwitchTip (grey) |

||

| Wagner Guard (black) | Trade Tip 3 (purple, yellow) | Titan SC-6+ (red, purple), Titan TR1 Line Striping (white) for road marking, Graco tips fitting the older RAC V guard and FARBMAX Silver (blue) |

| Silver (blue) | Wagner tips, Titan tips, Graco tips fitting the older Graco RAC V guard | |

| Titan Guard (black) | SC-6+ (red, purple), TR1 Line striping (white) | Wagner Trade Tip 3 (yellow, purple), Graco tips fitting the older RAC V guard and FARBMAX Silver (blue) |

Spray guards in the Airless Discounter shop

FARBMAX new (blue) and FARBMAX older version (orange).

Graco RAC V (Orange) + Graco RAC X (Blue) +Graco RAC XHD (grey)

Wagner TradeTip 3 Tip holder G-Thread 7/8″ (Black) and Wagner TradeTip 3 Tip holder H-Thread 11/16″ (Black)

6. Identifying a spray tip – types, colours and sizes

Types

Standard spray tips general purpose spray tips that can handle a wide range of materials. You will find the most “cross-over” possibilities using these spray tips. Materials possible for spraying include anti-corrosive paint, latex paint, acrylic paint, interior emulsion paint, exterior emulsion paint, roof coating, flame proofing and silicate. Its possible to use the smaller, narrow standard spray tips for lacquer spraying. Its also possible to use some of the wider, larger standard spray tips for spraying plaster or spackle.

Fine finish tips produce a softer, smoother finish than standard spray tips. Fine finish spray tips are used for cabinetry, furniture and interior trim work (for a smooth fine finish) example Graco FF LP spray tips: 210 or 310.

Low pressure tips are used primarily for spraying with pressures between 55 to 76 bar (800 to 1100 psi).

(Specialised) Heavy duty high pressure spray tips that can handle spraying pressures up to 344 bar (4989 psi) and others up to 530 bar (7687 psi). Road marking spray tips to produce consistent, even lines.

Standard |

Fine Finish |

Low Pressure |

Specialised – Heavy Duty |

Specialised – Road Marking |

| Graco RAC X / 10 (blue)

Graco RAC V / 5 (black) Graco RAC X / 10 (brown) wider orifice for thicker materials Wagner TradeTip 3 (yellow) FARBMAX Silver (blue) |

Graco FF LP (green)

Wagner TradeTip 3 Fine Finish (purple) |

Graco LP (green) and FF LP (green)

Wagner HEA ProTip (green) |

Graco (grey) XHD RAC (high-pressure) | Graco LineLazer (yellow) for road-marking, parking lots, warehouses and sports fields.

Titan TR1 Line Striping (white) for road marking |

Customer question: How can I tell if I’ve got a RAC X, RAC V, or RAC 5 tip? RAC V are RAC 5 spray tips and vice versa. RAC V / 5 are colour-coded black or yellow. RAC X are newer spray tips from Graco and are colour-coded blue, brown or green.

Spray tip colours

|

|

|

|

|

|

|

|

|

| Wagner Trade Tip 3 Fine Finish

Titan SC-6+ Synergy Fine Finishing Titan TR2 Fine Finishing |

Graco RAC X | Graco RAC X LP

Graco RAC X FF LP Wagner HEA ProTip |

Wagner Trade Tip 3

Graco LineLazer Titan TR2 Line Striping |

Titan SC-6+

Titan TR2 |

Titan TR1 Line Striping | Graco XHD RAC

Titan TR1 High Pressure |

Graco RAC 5 / V | Graco RAC X |

Please note: Wagner also have HEA (green) spray tips for entry level sprayers such as the Wagner HEA Control Pro 250 & 350 models. These HEA spray tips are not intended to be used for professionals. Instead choose the HEA ProTip spray tip, or another professional spray tip suitable for your material and job requirements.

Spray tip sizes

Spray tips are numbered from 108 all the way to 1235.

Lets look at some common spray tips for paint. If we tabulate the bore hole size versus the fan width, we will see a gradual increase in the size of the bore hole as the spray angle increases.

But this is a rough guide only.

You have quite a wide range of options between spray tips with the same spray angle but different bore hole sizes, or same bore hole size but different spray angles.

| 10 cm | 15 cm | 20 cm | 25 cm | 30 cm | |

| 4 inches | 6 inches | 8 inches | 10 inches | 12 inches | |

| 0.011″ | 211 | 311 | 411 | ||

| 0.013″ | 313 | 413 | |||

| 0.015″ | 415 | 515 | |||

| 0.017″ | 517 | ||||

| 0.019″ | 619 | ||||

| 0.021″ | 521 | 621 |

DID YOU KNOW? Graco Fine Finish tips are even-numbered 108, 210, 310, 510 etc

Bore Hole Size |

Coating Material |

| 0.009 to 0.013 | Lacquer or stains |

| 0.013 to 0.015 | Oil based paint |

| 0.015 to 0.019 | Latex paint |

| 0.021 to 0.025 | Thicket latex paint and smoother elastometric |

| 0.025 to 0.035 | Elastometric and blockfiller |

Please note: Do not rely on the spray tip number only, always consider the material you are using (viscosity of similar materials still vary) and the capability of your Airless sprayer (delivery rate, maximum working pressure etc).

7. A quick note on spraying technique

Perpendicular to the wall, 12 inches / 25 cm from the wall.

When spraying high walls or ceilings use a spray extension to maintain the optimal spraying distance.

Some plasters are sprayed further away from the wall.

Bend your knees when spraying the lower part of the wall to ensure the optimal spray angle and spraying distance is maintained.

8. A quick note on spraying pressure

Pressure (psi) |

Pressure (bar) |

Spray Tip Suggestions |

| 800-1100 psi | 55 to 76 bar | low pressure spray tips, some fine finish tips |

| 2000 to 2200 psi | 138 to 152 bar | some standard spray tips, some fine finish tips |

| up to 3000 psi | up to 207 bar | standard spray tips |

| up to 5000 psi | up to 344 bar | some standard spray tips*, heavy duty high pressure spray tips |

| up to 7687 psi | up to 530 bar | heavy duty high pressure spray tips |

*technology improvements and using higher quality materials means standard spray tips are able to withstand higher pressures. Please check your product packaging for the maximum allowed working pressure.

Customer question: Spraying pressure for fine finish or regular? I don’t think my pump has enough pressure, do you need more than 1600 psi? The answer to this lies in the material you are using and the type of Airless sprayer you have. Your pressure settings must be adjusted for the viscosity of the material as well as your chosen spray tip bore hole size. The delivery rate of your sprayer and environmental considerations are also factors. Its possible you have an entry level paint sprayer that is’t equipped to handle more demanding jobs and higher viscosity materials. If you can message us or call us and provide us with more information (material? Airless sprayer model?) we will be able to assist you further.

Customer question: Im using a FFLP 210 spray tip to spray my vanity cabinet (including doors and drawers). I’m hanging the doors on cup hooks and hangers but when I spray the primer the doors get pushed violently away. Am I using too much pressure? FFLP are fine finish low pressure tips. Does your Airless sprayer have a pressure guage? You will only need around 800 to 1100 psi (55 to 75 bar) to spray with low pressure spray tips.

9. Common application Airless spray tip guide

Spraying cabinets or cupboards

210, 310 fine finish spray tips.

Interior trim

210, 310 fine finish spray tips. Possibly even the 108 for a very narrow fan width for staircase railings. For taller baseboards you may even consider the 510.

Doors

310, 510 fine finish for doors. With many new doors you can opt for the wider 510, especially when placing them alongside each other and spraying before installation.

Fences and siding

310 and 510 fine finish spray tips.

311, 313, 411, 413, 415 and 515 – depends on materials on job requirements.

Interior and exterior walls with latex paint

515, 517, 519, 615, 617 and 619 for interior walls.

515 up to 617 exterior walls.

Customer question: Do you use a narrower fan width outside for less overspray? You can and some painters have, although this is personal preference. You may choose to use a narrower fan width outside during windy conditions to control overspray better.

Interior ceilings

Similar to interior and exterior walls. A popular spray tip amongst painters for spraying ceilings is the 619 spray tip.

BEGINNER HINT: Use smaller tips when starting out. As your technique and control improves, you can widen the bore hole size.

Stains |

Enamels |

Primers |

Interior Paints |

Exterior Paints |

Elastometrics and blockfillers |

| 0.009-0.011 | |||||

| 0.013 | 0.013 | 0.013 | |||

| 0.015 | 0.015 | 0.015 | 0.015 | ||

| 0.017 | 0.017 | 0.017 | |||

| 0.019 | 0.019 | ||||

| 0.021-0.023* | 0.021-0.023* | 0.021-0.023** | |||

| 0.025-0-035 |

*thicker latex paints may need wider bore hole sizes.

**smoother elastometrics may be able to use slightly smaller spray tip sizes.

Elastometrics, new construction walls and block fillers

621 to 1223 spray tips for your smoother elastometrics. Some painters have reported using spray tip sizes for elastometrics as small as 517. If you happy and it works for you, go for it.

625, … , 835, … , 1235 spray tips. You need sufficiently wide bore hole sizes to allow the material to pass through.

Customer question: What tips should I own? This depends on what you want to spray! If we had to choose a “one-size-fits-all” (not recommended). Perhaps the following:

If you starting out, a 310 spray tip can handle most trim work and cabinets. A 515 for walls. Then you can add a 619 for more coverage for interior walls and ceilings. For new construction a 1221 would be handy too!

10. Spray tip life span and replacing spray tips

140-190 litres (40-50 gallons) on a standard tip.

High quality tips can push out 225+ litres (60 gallons). This reduces dramatically when using the “worst paint” – material containing clay or other abrasive particles.

What happens when the tip wears out?

Are you noticing:

- The spray pattern developing bands of lighter and darker areas

- A smaller fan width, as if the angle of spray has decreased

- You are running out of paint faster than usual?

A worn out tip is noticeable when “tails” emerge on either ends of the spray pattern, when the fan width decreases or when more paint is being required to cover the same surface area.

This is due to the tip losing its shape and/or getting clogged.

A new tip is shaped much like a hot dog, it is long and narrow with rounded edges. As it’s being used the tip widens and shortens, becoming more like a burger bun. More material is then dispersed in the middle and less on the outside.

The paint delivery rate and surface coverage is compromised too.

Spray tip wear over time

Take the guess work out of spray tip replacement! Experienced painters know when their tips are worn, they might notice a “hissing” sound or more material coming out of the gun than before. But as a novice paint sprayer, you don’t need to guess, just replace the spray tip after a predetermined amount of material has been used. (150-200 litres, 40 to 50 gallons.)

11. Cleaning spray tips

Between coats you can just pop your spray gun with spray guard and spray tip intact into a bucket of water (for water-based materials).

For next day spraying or job completion, rinse thoroughly and use an egg-shaped container for cleaning.

You can also use cleaning needles and cleaning brushes, when material is clogged in the spray tip.

Just be sure to follow the safety pressure relief procedure when cleaning Airless paint spraying equipment.

Unclog RAC X and other reversible spray tips with a simple twist of the spray tip!

12. Troubleshooting common issues and concerns

Using smaller spray tips than the recommended range

Customer question: If the paint specification is use a 0.015- 0.021 tip and I use a smaller tip e.g. FF LP 210 what will happen?

Customer question: I am usinga 310 fine finish tip to spray an interior door even though the paint I’m using recommends using a 515 or 517 tip?

Customer question: I am spraying eaves and gutters using an exterior latex paint and they recommend an orifice size of 0.017. I was going to use a 517, but really like the smaller fan and finish of the 310. Is that too small for the material I am using, will it clog?

For the above questions. The customers are using the Fine Finish Low Pressure, FF LP spray tips from Graco. The recommended Airless spray tip orifice size is for standard spray tips. Because of their construction, you may be able to use these 310 FF LP in these stances. Of course, if the material is struggling to come through, choose a bigger spray tip or increase the pressure.

Seeing tiny pin holes forming in paint

Water-based primers may react with the wood causing tiny bubbles to form. Switch to an oil-based primer instead.

Love our content? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Questions or queries?

Have we left anything out? Let us know by commenting below.

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form or email us.

If you wish to purchase one of the products mentioned above, you can check them out in our online store.

Fill out a Contact Form on our website