Airless, airless, airless… a word both known and mysterious.

To put an end to this artistic blur once and for all, here is our complete article on airless, working techniques, choice of machines and main manufacturers.

We have already covered the subject at length and in detail on our blog.

As this blog is already a mine of information about airless, you will find many links in this article.

Feel free to click on them for more details.

Definition and brief history

Airless means “without air” and refers to a paint spraying process in which the sprayable material is sprayed at high pressure onto the surface to be worked on.

It is a mechanised spraying solution that enables fast, efficient and cost-effective spraying for building professionals.

Infographic : (r)Evolution of painting tools

Quand on sait que la première pompe airless a vu le jour en 1958, cela fait réfléchir.

A few years ago, we made our first infographic on painting.

Before getting to the heart of the matter on airless, why not take a minute to see how painting tools have evolved since the dawn of time.

These have also evolved as man has learned to master different painting styles and techniques.

The infographic on the revolution of painting tools allows you to become aware of the path taken from prehistory to the present day.

When you know that the first airless pump was introduced in 1958, it makes you think.

Infographic Painting Tools

Click on the image to view a larger size or here for the actual size.

Spraying technology

After this playful and light-hearted gap, let’s now take a look at how a painting station works.

Airless devices operate electrically, pneumatically (compressed air or compressor) or by means of a combustion engine.

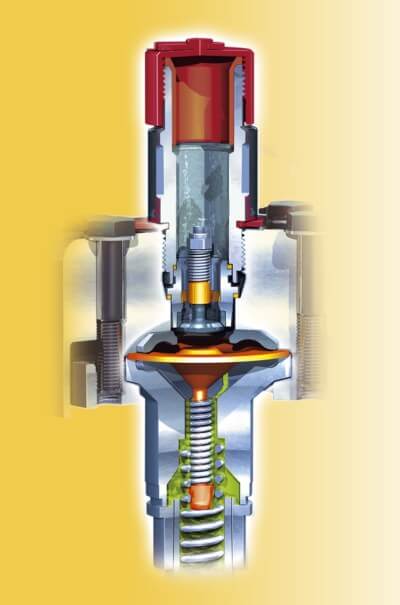

The pressure is built up by means of a piston or a membrane.

The flow is regulated by an inlet and outlet valve. The pressure is regulated by means of a pressure valve and a pressure relief valve. A pressure gauge shows the pressure.

The sprayable product is pumped through the suction system (rigid, flexible or funnel suction system) and redirected into the system.

The piston or the membrane creates the pressure and conveys the product through the outlet valve into the high pressure hose, through the gun and the nozzle to the surface to be painted.

Diaphragm or piston?

The choice of a piston or membrane machine can be decisive for your project.

To make the right choice, see our article about diaphragm and piston pumps.

Ultimately, it is a matter of personal choice between piston and membrane. But don’t forget: a diaphragm pump does not have enough power to spray plasters!

Piston pumps are capable of this, but only with Graco Mark V, VII and X pumps.

This is a pump diaphragm

Advantages and disadvantages of airless

Each process has its strengths and weaknesses. Here is a summary of the most important ones.

Positive aspects

If you are still unfamiliar with airless, the following may give you food for thought.

- Speed and working comfort

You have already seen videos about the speed at which airless painters work.

Speed means more building sites and less physical exertion.

Whether you don’t like to paint with a roller or your body can no longer keep up with the pace as before, a paint station can indeed make your work more comfortable.

- Project profitability

Money is the sinews of war, isn’t it?

By using an airless pump, you not only save on material, but you can also do more work on your own.

This is particularly interesting when you have large areas to renovate in a short time and with few personnel.

- The quality of finish

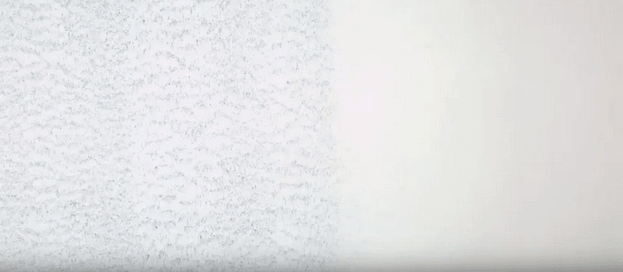

It can be observed by eye and by touch.

While you will often need to apply several coats with a roller, this will not be necessary with an airless spray gun.

On the left, the result with the roller and on the right the result with the airless gun.

Furthermore, it is particularly suitable for rough or hard surface structures such as plaster, stucco or even radiators.

No more hours of trying to get the paint into all the corners and holes in the substrate.

- Machine versatility

A common question is: Can I use a pump for plaster and interior paints?

To a certain extent and with the right accessories, it is possible to use the same machine for a wide range of materials and construction sites.

Negative aspects

Rather, they are prejudices due to misuse or misconceptions about airless.

- Masking of surfaces

As with brushes and rollers, surfaces must be protected.

This, even if it can be restrictive, should not make you lose sight of the fact that the time you invest in masking is time you will save over the entire duration of your work.

- Cleaning time

Another anti-airless argument is the so-called tedious cleaning of the spraying equipment.

This prejudice is unfounded, because cleaning an airless pump only takes a few minutes, just like cleaning rollers and brushes.

- The overspray

Airless overspray is largely the result of incorrect configuration of the machine or its accessories.

With optimal pressure adjustment and careful nozzle selection, mist formation and masking effort can be significantly reduced.

Airless paint manufacturers and products

The three leading players in the airless market for construction professionals are Graco, Wagner and Titan.

As Airless Discounter is primarily a reseller of airless spraying, we do not recommend any particular material manufacturer.

However, we regularly test airless paint and coating manufacturers with our machines.

This enables us to better advise our customers in their choice of airless pumps.

Feel free to browse through our blog to find spraying information for a particular product.

Sprayable material

Is there a machine that can spray all materials? The answer is clearly no, but there are compromises.

However, for each material there are one or more solutions.

Here is a list of the most common products sprayed by airless:

- lacquer

- woodstain

- primary

- acrylic

- facade painting

- anti-rust

- fire protection

- wallpaper glue

- airless coating

- roof covering material

- bitumen

Working techniques

Let’s get to the heart of the matter and see in more detail the important points to paint well with an airless spray gun.

How to spray paint?

You have to respect certain rules in order to have a good quality finish.

Here are the main steps to follow:

- The distance from the support (approx. 25 cm).

- The speed of application (not too fast, not too slow).

- The spray angle (always 90 degrees).

- The position of the arm (always be in motion before pulling the trigger on the spray gun).

- The overlaps during passes (50/50 strips).

And then: do you make the ceiling before or after the walls?

If you project two different shades (one on the ceiling and one on the walls), you do the ceiling last.

You will simply have to protect the walls with plastic sheeting to avoid any inconvenience.

This is much easier than having to laminate an entire ceiling, isn’t it?

If you spray a single colour, then it doesn’t matter as long as you paint everything wet on wet at the same time.

From masking to spray painting: we have detailed in our airless spray painting guide how to paint well with an airless spray gun.

What accessories should you choose to carry out your project?

In addition to the right machine and the right accessories for every job, there are some accessories that can make your life easier such as:

-

Low pressure tips

They have been on the market since 2017 and allow spraying with less pressure (up to 50%) than conventional airless nozzles.

If you’re afraid of fogging, this is the ultimate solution, not to mention the quality of the finish.

-

Airless extensions

Between 25 and 180 cm, the extensions are extensions that are attached to the end of the spray gun.

They allow many spraying jobs to be carried out at height more easily and quickly than with a spray gun or roller.

-

Anti-spitting valves

Very practical accessories, especially for work with large extensions to avoid dripping on the support.

An anti-spitting valve can really save your life on a building site.

Please note that the tip size must be adapted to the material and the working area.

In the following article, we show you how to choose the right airless nozzle.

And don’t forget: don’t save a few euros by not wearing a protective mask!

Even though many professional paints are now water-based and especially if you are in the trade, remember to protect your lungs when spraying.

Comparison airless & roller

Which is better: painting with a roller or an airless spray gun?

In addition to the final cost effectiveness and working speed, you can compare the covering power and the final result of both types of application.

Opacity, surface quality and finish

Due to the overlapping working technique applied (50/50) with airless, it was possible to achieve a flat and uniform surface with a high-quality finish in one operation.

The structure of the roller is clearly visible and palpable when touching the wall, while the structure produced with the airless spray gun is much smoother.

Although some techniques such as droplet rolling are easier, those requiring flat surfaces (such as after plastering) get a nice finish after airless spraying.

Operating speed

The airless spraying process is at least 3 times faster than traditional painting.

This translates into a much higher economic efficiency, especially for medium and large surfaces.

Buying a paint sprayer or consumables

This article is slowly coming to an end. Here are some final tips to help you with the right paint sprayer for your renovation project.

For an occasional job

You are a private individual and would like to renovate your house or flat?

But you don’t want to invest a lot of money in a machine.

We fully understand your point of view, but pay attention to the offers of low-price paint sprayers from DIY shops and supermarkets.

And if you prefer to test before you invest in a machine, why not rent an airless pump from a professional.

For a regular job

You are a building professional and you are convinced that this technique is the future of your profession.

But you want to be sure that you handle the machine well and do a good job.

That’s why we have set up an airless training centre in Berlin.

In the U.K and Ireland, you can contact our partner PaintTech Academy.

Advice before buying

When advising you on the choice of the right painting station, we take into account your requirements and the field of application.

We can then offer you a pre-selection of airless pump models and accessories suitable for your site.

Love our content ? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Questions or queries ?

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form or email us.

If you wish to purchase one of the products mentioned above, you can check them out in our online store.

You can also visit us at our service base during office hours.

Fill out a Contact Form on our website