# paint gun pressure gauge

A pressure gauge is a scientific instrument or manometer that measures pressure. This pressure can be in liquid, gas, vapor, etc. In our field of activity, a paint gun pressure gauge is used to know the exact pressure used during your airless spraying.

Even though digital displays are becoming more and more common, many airless pumps are still equipped with a pressure gauge. Robust, accurate and reliable, this object has survived the centuries without a single wrinkle. The perfect opportunity for us to reveal more information about pressure gauges!

Example of pressure gauge on FARBMAX M10 Plus airless pump

What is a pressure gauge?

A pressure gauge (also manometer – from the ancient Greek μανός manós “thin” and μέτρον metron “measurement”, “scale”) is a measuring device for recording and displaying the physical pressure of a medium (liquid, gas).

In most applications, relative pressure is measured, i.e. in relation to atmospheric pressure. In contrast, instruments for measuring absolute pressure (e.g. barometers) use vacuum as the reference pressure. Differential pressure gauges, like the others, measure a difference in pressure, but between any two systems.

On the Graco manometer below, you can see bars in green (= absolute pressure) and Mpa in red (= Megapascal – relative pressure). Even if only one of these pieces of information is on your gauge, you can easily make the connection.

As for the Psi in black, it is the abbreviation for “Pound-force per square inch”, i.e. the Anglo-Saxon unit of measurement of stress and pressure. This explains the indications you can hear on some English / American videos of airless painters.

How does the pressure gauge measure pressure?

In a pressure gauge, one end is connected to a gas tight seal to test the pressure source. The other end of the tube is left open to the atmosphere and will be subjected to the pressure of approximately 1 atmosphere (atm).

In addition, as the test pressure is greater than 1 atm, the liquid in the column will be pushed down by the pressure. In addition, it will cause the liquid in the reference column to rise by an equal amount.

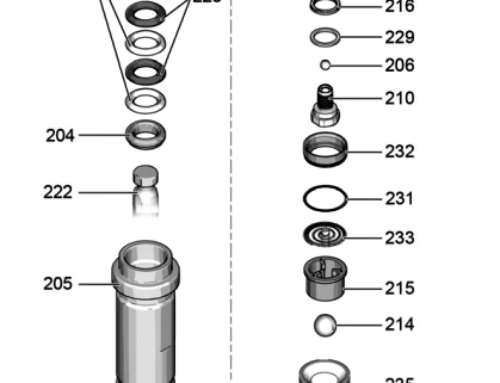

Below you can see how the mechanism works in practice. A meter contains a metal cylinder. The elastic cylinder of the meter is pressed when measuring a gas or fluid. The cylinder is then deformed, which is converted into a meter, allowing you to read the result.

Mechanism of a tube pressure gauge – Via Wikipédia

There is a bubble in my pressure gauge, is this normal?

We’ve had the request before so yes it is quite normal and even intentional.

The air bubble is necessary to dampen the internal pressure to ensure accurate readings. It is necessary for the air bubble to be present for the gauge to work properly, as the air has a dampening effect on the gauge.

In fact, you should be concerned if there is no air bubble in your gauge!

Do I need a pressure gauge to know the pressure used on my airless pump?

In addition to mechanical pressure measurement, there is also electronic pressure measurement using a digital display.

Some professional airless pumps, such as the Graco ProContractor, are equipped with an LED display, which automatically measures certain information, including the pressure used.

This is very practical, but adds a certain price to the machine and is therefore not accessible to all budgets.

Digital display on a Graco Mark VII ProContractor

On many Wagner and Graco DIY pumps there will be no pressure gauge fitted to the machine. Instead you will have a gauge or knob (often 1-5) that allows you to raise/lower the pressure. You will have to play around to find the right pressure for your spraying.

However, if you prefer to work with accuracy, a FARBMAX pressure gauge costs a few dozen euros from Airless Discounter – contact us to see if it can be connected to your airless pump model.

How do I connect a pressure gauge to my machine?

On some airless pumps, no pressure gauge or display is available. If this is your case, we strongly recommend that you install a pressure gauge on your machine to know the exact spray pressure.

Not only will this help you to work better, but it will also prevent you from working with too much pressure and thus avoiding any overspray. Users have a tendency to turn on the pump when they are unsure of the pressure. However, proper adjustment of the pump pressure is the basis for good airless painting.

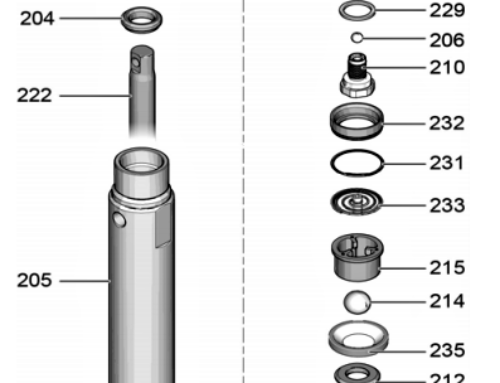

As for the assembly itself, nothing could be easier. A pressure gauge connects to the hose where your hose is connected to the pump: unscrew the hose, connect the pressure gauge to it and put the hose back on the pressure gauge outlet.

Mounting a pressure gauge on a Titan pump

Do I need a fitting?

It is possible – it depends first of all on the thread on your machine and of course on the pressure gauge itself. To find out this information, consult the user manual of your airless pump and find the part number. If needed, you can find all our fittings here.

On our site we have the original Graco and Wagner pressure gauges, as well as compatible Farbmax branded items. Some have a radial shaft, others have an axial shaft, and are supplied with or without a fitting.

If in doubt, please contact us to check with you which gauge is compatible with your machine before ordering.

Love our content ? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Questions or queries ?

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form or email us.

If you wish to purchase one of the products mentioned above, you can check them out in our online store.

You can also visit us at our service base during office hours.