Today we received a request from a customer regarding converting Airless to an AirCoat or air-assisted paint spraying system. The customer is using a Graco ST Max II 495 Airless device and would like to converst this sprayer to operate with the air-assisted spraying process. In the following blog post we clarify the terms AirCoat, and air assisted spraying. We clarify the difference between Airless and air assisted spraying and their advantages and disadvantages. In addition, we show which components are needed to convert an Airless device to an air-assisted spray system.

is it possible to use a Graco G40 spray gun to my Graco ST Max II 495 sprayer with a 420 l / min compressor?Thank you in advance,Jim the Painter

What does AirCoat or air-assisted spraying mean?

There are many types of phrases that are used to describe the air assisted spraying process. The company Wagner has had the term “AirCoat” trademark protected. Other manufacturers use terms such as aircombi, or air-assisted spraying. Ultimately, all these terms describe the same process. Basically, it is an Airless sprayer with the addition of air via a second hose to the spray gun. This results in some advantages, like a softer spray pattern.

What are the advantages of AirCoat / air-assisted spraying?

- softer spray pattern, finer atomization, no accumulation of material on the edges

- high quality surface finish

- reduction of overspray

- higher surface area compared to vessel gun or HVLP

The aircoat or air-assisted spraying process is mainly used when high-quality surfaces are desired. Most of our customers in the field of aircoat technology are carpenters, cabinetmakers, work on doors and windows or in booth construction.

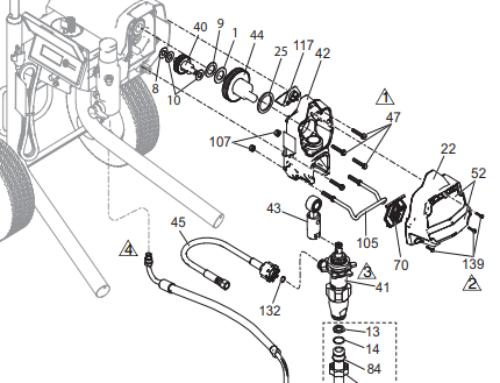

What is needed to convert Airless sprayer into an AirCoat / air-assisted spray system?

Converting a classic Airless device to an AirCoat or air-assisted airless device is easy. The following components are required:

- pressure control unit

- double hose

- special pistol (for example Wagner AC 4600 or Graco G40)

- compressor

In this video our technician Hartmut is showing how to convert a Wagner SF23 Airless paint sprayer into an air-assisted machine in a few steps.

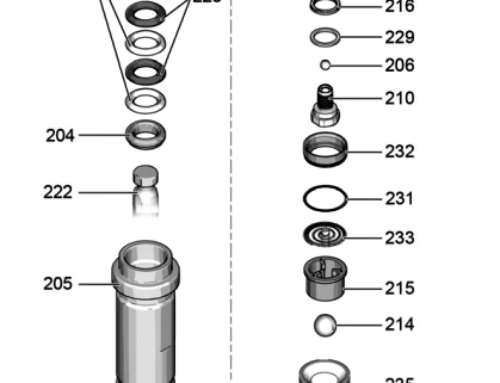

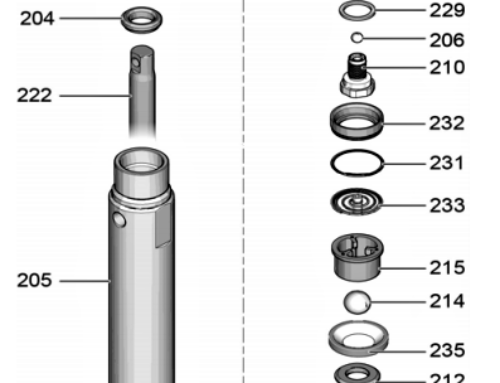

Pressure control unit

The pressure control unit allows the user to precisely regulate the compressed air coming from the compressor and thereby control the air flow to the gun. To do this, the compressed air control unit is mounted on the airless device (pictured here on the frame of a Wagner SF 23 Plus). The compressed air hose of the compressor is connected on one side. Another hose connects the pressure control unit to the gun. The compressed air supply happens at a low pressure, max. 2.5 bar.

Double hose

The double hose consists of two hoses, the paint hose and the air hose. For reasons of convenience, these two hoses are connected together to form a double hose. As a rule, the two hoses are equipped with different threads in order to avoid confusion when connecting the hoses. For most double hoses, the paint hose has a M16x1.5 thread and the air hose has a 1/4-inch thread. Double hoses are 7.5 m long. If a longer hose is required, two double hoses can also be connected to the corresponding connectors (1/4-inch connector for the air hose, M16x1,5 connector for the paint hose). In the case of piston pumps, the hose as usual is important because it has a balancing effect, so it may make sense for electric piston pumps to use 15 m long hoses to avoid repercussions on the spray pattern.

AirCoat / air-assisted spray gun

You can find several air-assisted spray guns on the market. The most common models include, for example, the Wagner GM 4600 AC or the Graco G40. These guns have special nozzles.

Compressor

Paint sprayers have a motor that builds up a strong pressure so that the material can be sprayed. Air driven pumps require an additional compressor through which compressed air is pumped to the spray gun. Please note that you should opt for a bigger compressor if you have air-powered pumps. This is because the compressor needs to feed air to drive the air-motor and the piston of the pump and air is needed for the gun. An electric driven pump such as the Graco 495 or Wagner SF 23 Plus just needs compressed air for the gun. Therefore less air and smaller compressors are needed.

Love our content? You can find more here:

Check out our Airless Discounter YouTube channel

Airless Discounter Instagram account

Questions or queries?

For any further questions or if you would like to get your hands on one of these products seen in this article, you can contact us on +49 (0) 30 220 15436, fill out our contact form or email us. If you wish to purchase one of the products mentioned above, you can check them out in our online store. You can also visit us at our service base during office hours.